Sika Industry with the Advanced Resins Team is a world leading provider and developer of high performance resins for the tooling, composite and electronic industry.

High Quality EP and PUR Systems

Sika offers customised solutions with local support and worldwide availability from the model to the part, including the appropriate structural adhesives.

In addition, we offer casting resins and functional coatings for dielectrics and for filters.

Our products, technologies and expertise cover a wide range of applications:

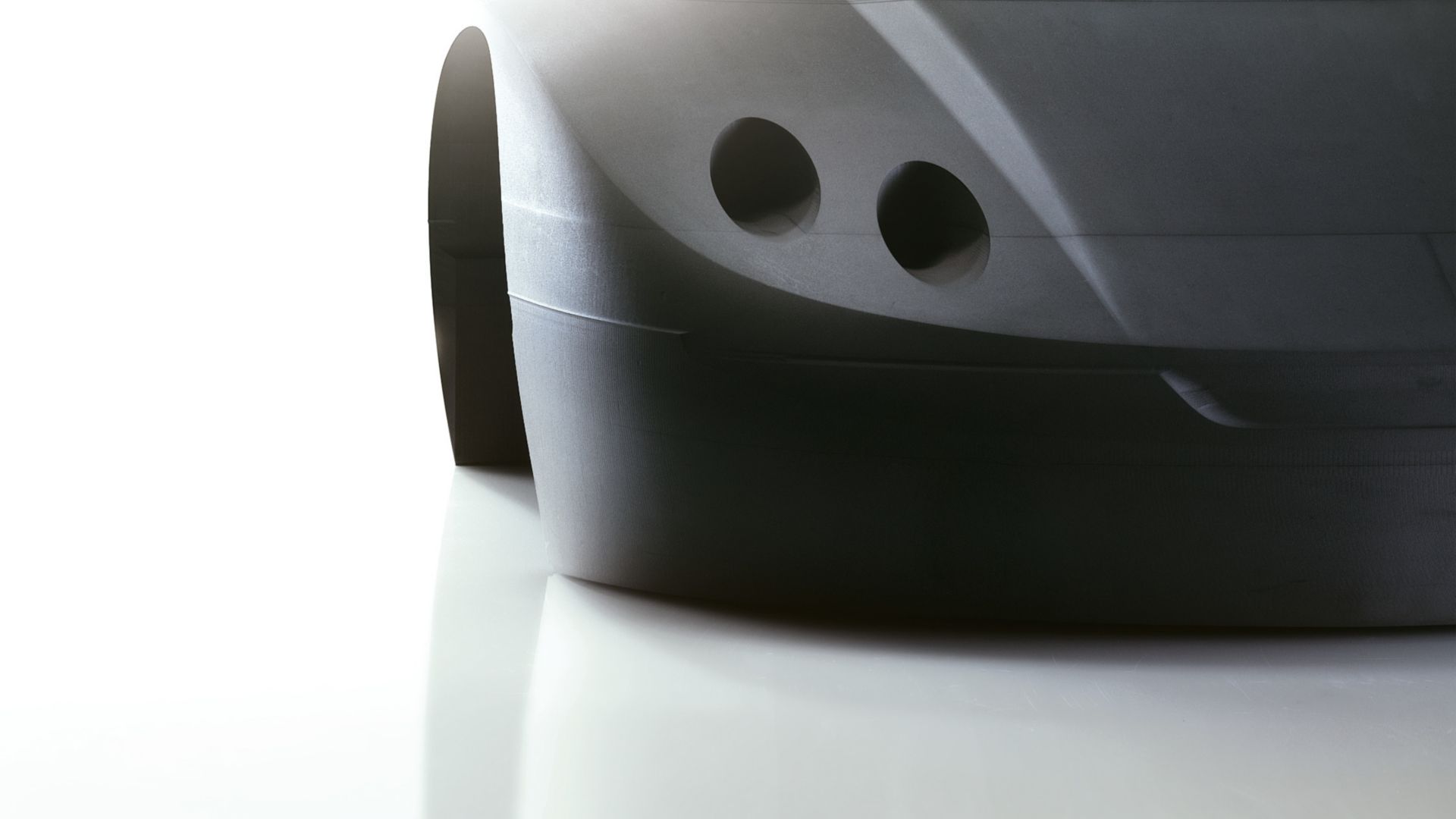

- Block Materials

- Model and Mold Making Pastes

- Gelcoats

- Composite Resin Systems

- Electronic Potting and Casting

- Epoxy and Polyurethane Casting

- Low Pressure RIM Systems

- Elastomeric Casting Resins

- Technical Casting

> 1,000,000

SikaBlock® boards have been used last 2 decades for the production of design/master models and for manufacturing tools

WIDE RANGE

of different pot lives, heat resistance properties or transparent effects with SikaBiresin® epoxy and polyurethane casting resins